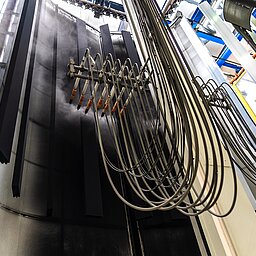

The adhesion between the powder and the object is a result from the electrostatic charge. In the subsequent baking process and dependent on the process conditions of the powder supplier, the object is baked in the oven after the coating process.

Powder coating is a sustainable alternative compared to classic liquid painting. A significant advantage of powder coating is the environmental friendliness. The process is harmless to health and environment because it is free of volatile organic compounds (VOCs), TGIC and heavy metals.

Advantages

Further advantages are the recovery of the overspray, very high corrosion resistance and high mechanical resistance of the parts as well as high deformability and weather resistance and good electrical insulation properties.

This process creates a homogeneous surface. As our customer, you determine the color and structure of your surfaces.

Our powder coating process is carried out according to the valid guidelines of Gütegemeinschaft für die Stückbeschichtung von Bauteilen e.V. (GSB).

We are listed with the company number 047.

deutsch

deutsch  Niederländisch

Niederländisch